DAMTEC® vibra-3D

Hard decoupling mat made from high-quality rubber granules

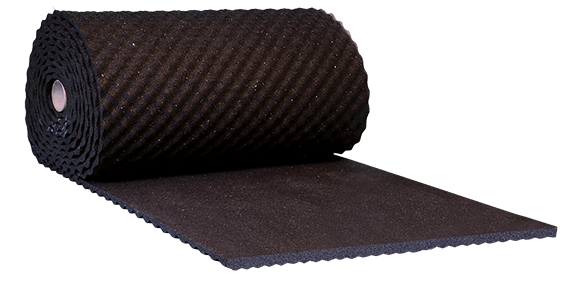

DAMTEC® vibra 3D is an insulation material made from high-quality recycled rubber offered in several texturing and thickness options. Its upper side is smooth with light granular texturing; its lower side is available with different dimple patterns. DAMTEC® vibra 3D is used in extremely sensitive applications, i.e. under compressive stresses ranging from 0.005 N/mm² to 0.050 N/mm².

|

|

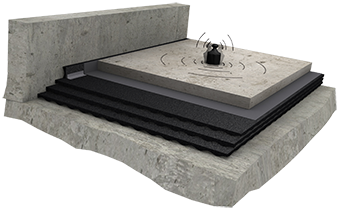

Single layer: f₀ ≥ 18,0 Hz Average compressive stress ≤ 0.05 N/mm² The natural frequency f₀ is dependent on the product thickness and the weight supported. |

||

|

|

|

|

Two layers: f₀ ≥ 14,0 Hz Average compressive stress ≤ 0.05 N/mm² The natural frequency f₀ is dependent on the product thickness and the weight supported. |

|

|

|

Three layers: f₀ ≥ 10,0 Hz Average compressive stress ≤ 0.05 N/mm² The natural frequency f₀ is dependent on the product thickness and the weight supported. |

|

|

|

Technical data:

|

Material: |

High‐grade granules of recycled rubber with PU elastomer bonding agent |

|

Colour: |

black |

|

Surface: |

granule structure, with profile on one side |

|

Density: |

approx. 600 - 700 kg/m³ |

|

Tolerances: |

Length and width ± 1.5%, thickness ± 1.0 mm |

|

Dimensions: |

Roll width: 1,250 mm Thickness: 8/4, 17/8, 23/12 mm Roll length: 8,0 m |

|

Tensile strength: |

approx. 0.3 N/mm² (ISO 1798) |

|

Elongation at break: |

approx. 45% (ISO 1798) |

|

Temperature resistance: |

-40° bis 80°C |

|

Fire resistance: |

Efl (ISO 11925/ EN 13501-1) |

|

Maximum pressure: |

0.05 N/mm² (according to EN 826) |

|

Dynamic bedding modulus: (EN 29052) |

6/3: 0,015 ‐ 0,250 N/mm³ 10/5: 0,006 ‐ 0,200 N/mm³ 17/8: 0,004 ‐ 0,140 N/mm³ 25/7: 0,003 ‐ 0,120 N/mm³ (depending on configuration, load and frequency) |

|

Natural frequency (one layer): |

8/4 = 30Hz, 17/0 = 20 Hz, 23/12 = 17 Hz (bei σ = 0.05 N/mm²) |

Further characteristic values and details on request